H-Frame scaffolding is a platform for plastering, painting, insulation and cladding work on the internal and external walls of buildings. It consists of vertical, horizontal, and diagonal sections and is known for its rigidity, reliability and safety features. H Frame consist of welded frames with 48 OD vertical pipes, braced together with scissor type cross braces secured by nut-bolts. The H-Frame scaffolding system consist of modules. One module comprises of Two H Frames and two Cross bracings for connection. A high-quality range of Scaffolding H Frames is being offered to the clients in different specifications. These products have rigid welded frame of horizontal and vertical pipes. Further, these pipes are interconnected by scissor type cross braces by the help of pins and spring clips. Moreover, we can customize these products as per the exact details provided by the esteemed patrons, which has helped us in attaining their maximum level of satisfaction.

CUPLOCK's unique locking action makes it the fastest, safest, most economical & widely-used scaffolding system in the world. The success of CUPLOCK lies in the ‘node point’ or fastening method. Four horizontals can be fastened at one time, making a very rigid connection. The horizontals bear directly on to the verticals and are firmly clamped by the action of the top cup. There are no loose parts to lose. CUPLOCK is made from the highest quality steel providing great strength while being light and easy to handle. When investing in equipment, it must as versatile as possible and CUPLOCK is ideal for many applications: formwork, support, general access, circular scaffolding, mobile towers and many other uses. CUPLOCK is now widely used in industries as diverse as ship building, power plant, refinery maintenance and conservation of monuments. Speed of erection and simplicity are the keys to CUPLOCK's success. Designed to be tough, CUPLOCK is highly resistant to damage. CUPLOCK will provide you with important cost savings as a result of its speed of erection. It can be erected by unskilled labour; easily stored, maintained and can be used in a variety of applications.

Aluminium scaffolding can require less care than steel due to the deterrence of corrosion and rust from humid areas and weather. The light weight system will also allow less wear and tear on the user, thus providing more enthusiasm in constructing the product and a longer physical stab. Aluminium scaffolding is a lightweight temporary structure used in construction, maintenance, and repair projects. It offers a secure work platform at heights and is easy to assemble and disassemble. Different scaffolding systems are available for sale or rent to match specific site requirements.

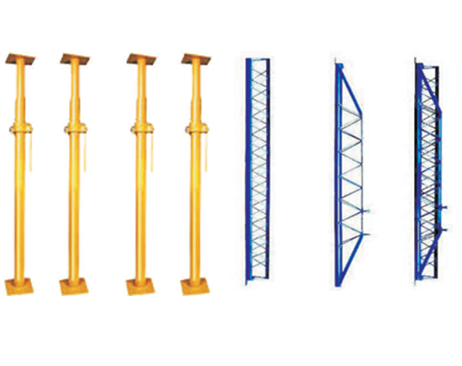

Props Sleeve:

Prop Sleeve is provided with casted/ forged nuts. This sleeve can be adjusted to any length within its range which is convenient for using. It is used for supporting concrete slab, beam, timber and formwork which is strong and reliable for interior building construction.

Span : Span, they are an integral structural construction scaffolding component of a construction scaffold, providing support to the overall structure. They can be adjusted as per the need and are basically used to support floor forms while laying slabs. These are the most advanced telescopic centring systems that basically used to support floor forms while laying slabs. This versatile system can easily be used and erected by unskilled labour. It virtually eliminates vertical propping and permits free space beneath the spans. Spans consists of an inner and an outer member.