Rebar bending machines are usually used for accuracy of bending angles. The machine is suitable for bending wide varieties of steel bars, TMT, and reinforcement bars etc used in construction. It is capable of bending the toughest rebars and its application is very extensive. The machine is suitable for contractors or construction companies to carry out different operations on rebar according to their requirements. It contains long steel shafts that can require bending before being used in construction. Different types of bender machines are applied for bending the rebar in the construction industry. All the types of benders differ in design and engineering, strength, technology and use. Apart from bending steel bars, the different machines also provide unique functions and capabilities based on the task that is needed to perform.

Model B 42 (GW 42A)

Model B 50 (GW 50)

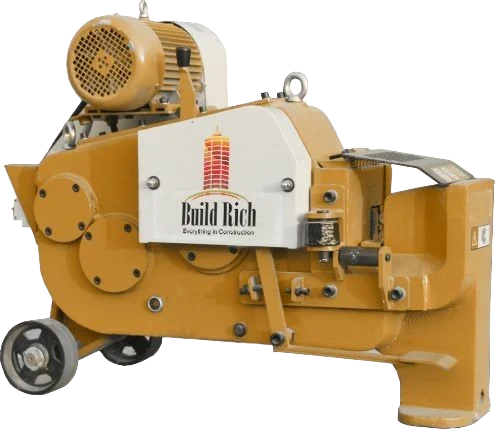

Steel bar cutting machine is used for rapidly cutting various gauge TMT Bars. Steel bars are extensively used in construction nowadays to reinforce concrete. The strength and thickness of steel bars can be easily attained by using these machines. There are several benefits of using steel bar cutting machine in construction. Firstly, it increases the speed of your work and cuts down the time taken by you. Secondly, it also helps you to do multiple jobs in a day and gives you more time for other work. Thirdly, it saves your money as you do not have to use and pay extra money for electricity, which is essential in today’s economic environment.

Model C 40 (GQ 40)

Model C 50 (GQ 50)

Elevate your metalworking capabilities with our cutting-edge Ring Making Machine. Precision-crafted and designed for efficiency, this machine empowers you to produce flawless rings with ease, catering to diverse industries such as jewelry, construction, automotive, and beyond. Boasting versatile customization options, our machine allows you to create rings of varying sizes, shapes, and materials, ensuring flexibility for a broad range of applications. With user-friendly controls and durable construction, our Ring Making Machine streamlines your workflow, providing efficient and consistent results. Whether you're a jeweler aiming for intricate designs or part of the manufacturing sector, invest in excellence with our Ring Making Machine and experience unmatched craftsmanship in every ring you produce.

Ring makeing machine

Upgrade your construction projects with the precision and efficiency of our Bar Threading Machine. Engineered for accuracy and versatility, this advanced machine ensures secure and reliable threading of reinforcing bars, contributing significantly to the structural strength and durability of your buildings and infrastructure. With high precision threading, efficient operation, and a user-friendly design, our Bar Threading Machine stands out for its robust construction and compatibility with various bar sizes and materials. Invest in this powerful solution to enhance the integrity of your structures, save time and costs, and experience seamless threading for diverse construction applications.

Bar Threading

Transform your sand screening process with our advanced Vibratory Sand Screening equipment. Engineered for efficiency and precision, our machine is a game-changer in the construction and landscaping industry. Offering high-performance screening, it efficiently separates sand particles based on size, ensuring a uniform and refined material for your projects. With a user-friendly design, the Vibratory Sand Screening machine streamlines operations, saving valuable time and labor costs. Its versatility makes it an ideal solution for various applications, from construction sites to landscaping projects. Invest in our Vibratory Sand Screening technology for reliable, efficient, and high-quality screening, ensuring your projects are built on a foundation of refined and uniformly graded sand.

Vibratory Sand Screening Machine