Slab Trolley that we are offering is used at a construction site in order to convey cement, concrete, and other materials used for building work made of quality-tested alloyed metal that is capable of standing impacts and rust. Due to its high build quality and capability of standing heavy shear forces, this Slab Trolley does not degrade in quality or become inferior in the long run. We hold the capability of supplying the trolley and that too at a cost-effective price.

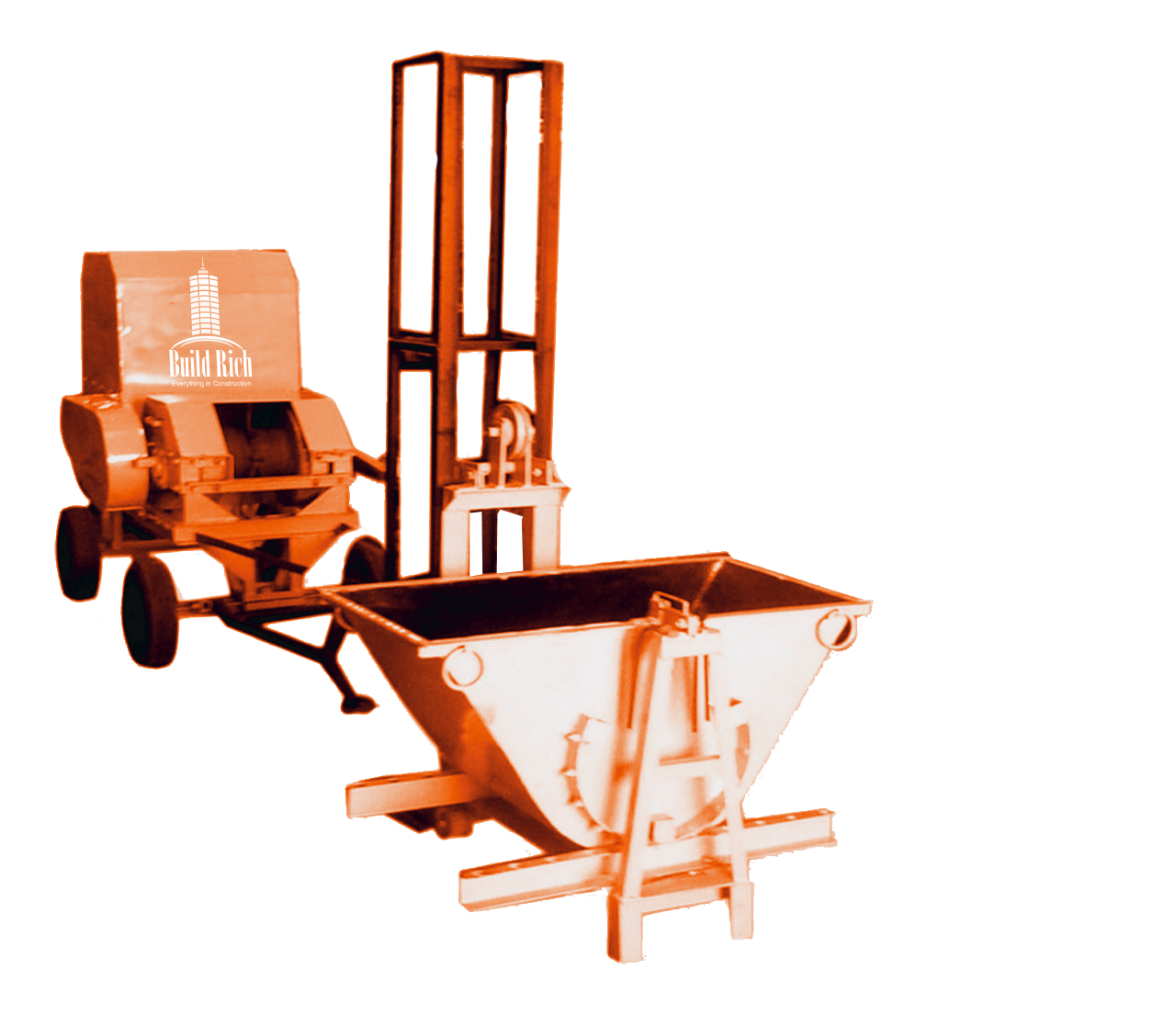

Tower Hoists are heavy duty and require minimum maintenance. They are used to lift concrete and other construction material for slab construction. The scaffolding provided with the Tower Hoist ensures safety at construction sites.

These Builder tower hoist machines are with a loading capacity of 350 kgs / 450 kgs. Tower is fabricated by use of angles. Winch is powered by a suitable capacity engine. Engine and chain are covered. Optional safety carriage is also available

The bucket is provided with locking system so as to avoid any accidents which may be caused due to the working of the bucket. The bucket has to be straight when concrete is getting filled up while during pouring of concrete the bucket will be tilted to one side. The bucket lifting and holding mechanism is from the tower hoist operating handle located on the trolley mounted main frame. The frames of the tower hoist can be quickly bolted to start the hoist in short time.

Painting & Repairs of Exterior Building Glass/ Aluminium Cladding. External Plastering & Brick Work, Chimneys, Hording/ Shipyard Maintenance, External building maintenance etc.

Scaffold tubes, often referred to as scaffolding pipes and poles, are made of lengths of Mild steel tube. Due to being cost-effective, b and secure, scaffolding tubes are ideal for creating support structures in construction work.

Concrete Mixing Tray, which is widely used in several on site construction buildings for the purpose of mixing concrete. Its efficient usage ensures that the mixing of soil and mud. In this tray Mortar and concrete are mixed. Mixing of soil and mud into mortar can be avoided by using this tray.

In the realm of construction scaffolding, crucial components such as the Bottom Cup, Top Cup, and Ledger Blade play vital roles in ensuring stability and reliability. The Bottom Cup, crafted from high-strength steel, serves as a foundational element, collaborating with a base plate to establish a secure base for the scaffolding structure. Meanwhile, the Top Cup, meticulously designed with steel and cast or ductile iron, proves indispensable in building construction and marine engineering. Its advanced features, including electro-galvanized or natural surface finishing, facilitate easy assembly and disassembly, boasting skid-protected design, durability, rust-proof construction, and physical stability. Additionally, the Ledger Blade, also known as runners, horizontally runs along the scaffold's length, providing essential support for the working platform, further enhancing the overall integrity of the scaffolding system.

Lay Down Bucket for Tower Crane is extensively used to carry ready concrete mixer from one place to other. Our products are manufactured by our professionals by using good quality raw material and advance technology. A concrete bucket delivers concrete by means tower crane. It has a bottom opening to allow concrete to flow out when in-place. Concrete buckets equipped with hydraulic or pneumatic gates shall have positive safety latches or similar safety devices installed to prevent premature or accidental dumping. Concrete buckets shall be designed to prevent concrete from hanging up on top and the sides. Concrete Bucket Capacity: 0.3 To 5 Cu.

Wallers are designed to transmit all loads from the soil through the retaining wall to the steel tie bars and to align and brace the wall in its position. In many applications, a steel waler or reinforced concrete beam is used to transfer retained loads evenly between tie rod connection points. These are used to hold form work panels / shuttering plates / shuttering ply. They act as primary beams to be used with Tie Rod to hold the form work.

Shikanja is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. Shuttering Clamps are mainly used in the construction industry. They are used for holding shuttering for beams and columns. These Clamps can also be customized as per the clients' specifications.